Optimized fuel pump body

Redeveloping an existing fuel pump body to imrpove fuel flow and performance.

Development process

-

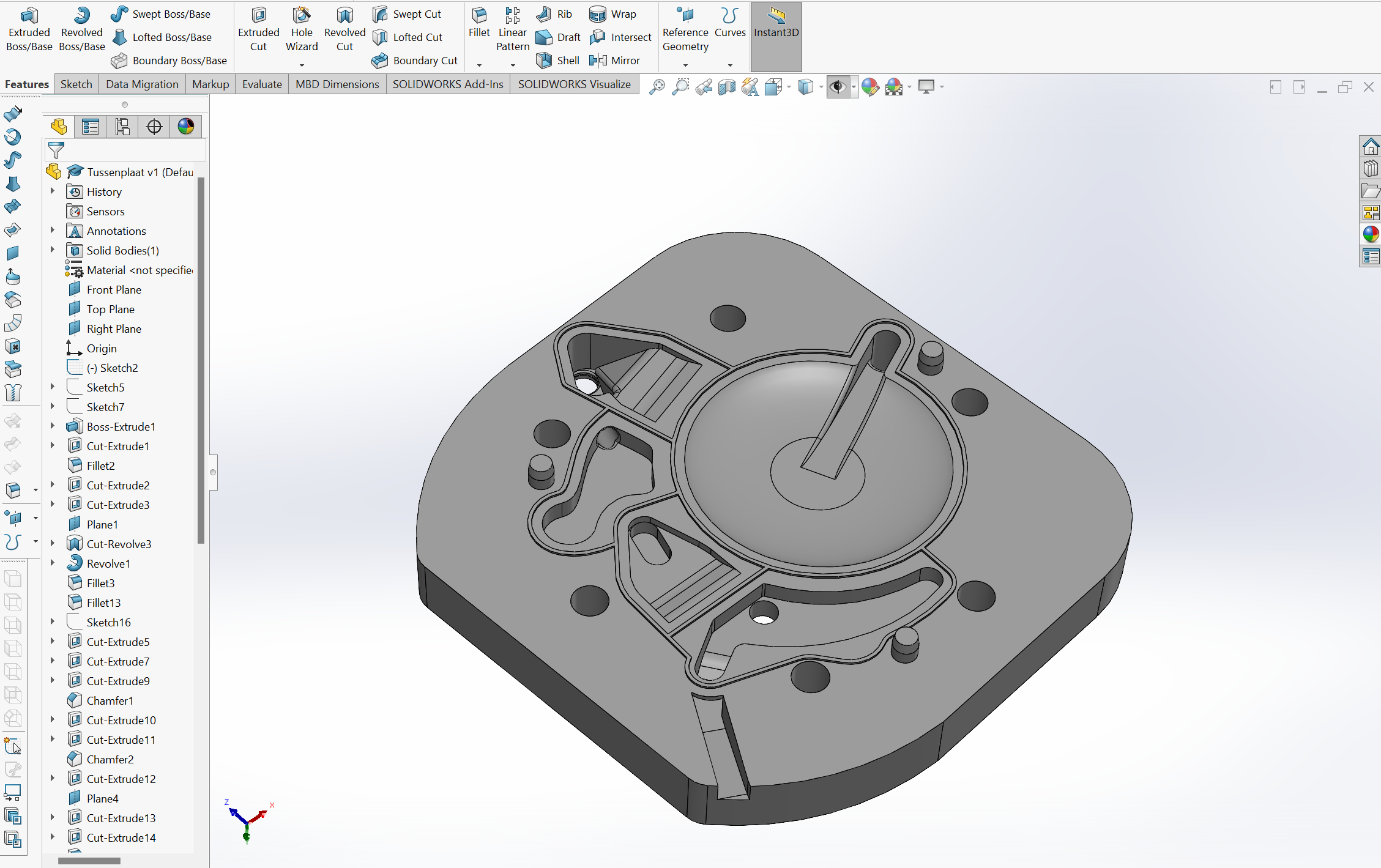

Reverse Engineered & optimized in CAD software

By first accurately measuring the original part and remodeling it in CAD software we had a strong base model that we could improve upon. Afterwards we finetuned the chambers and channels of the part. This way we were able to improve fuel flow and minimize turbulance.

-

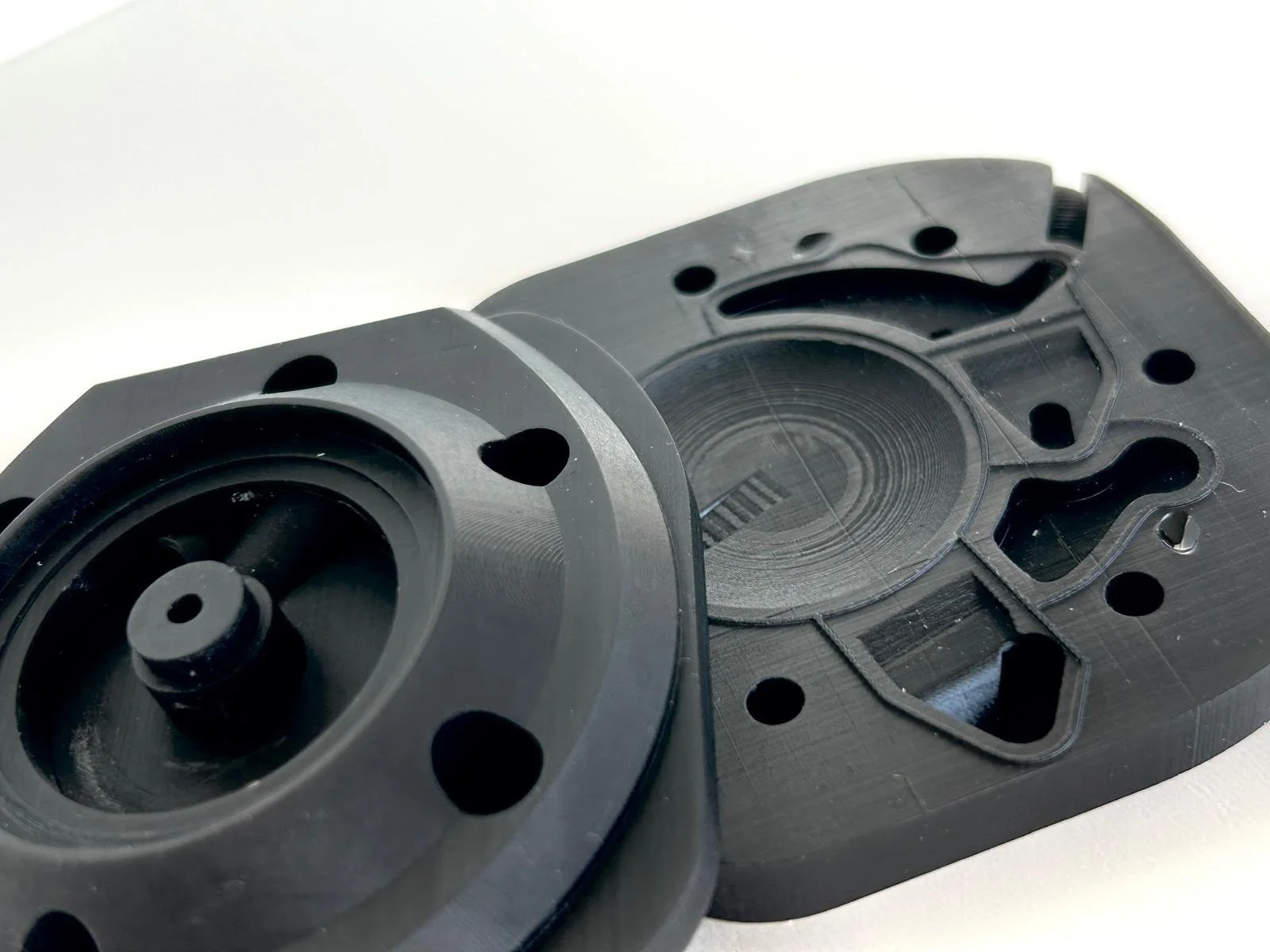

3D printed

The parts were 3D printed with a high grade industrial material by Loctite through DLP printing. Allowing it to resist the high temperatures and vibrations from the engine.

-

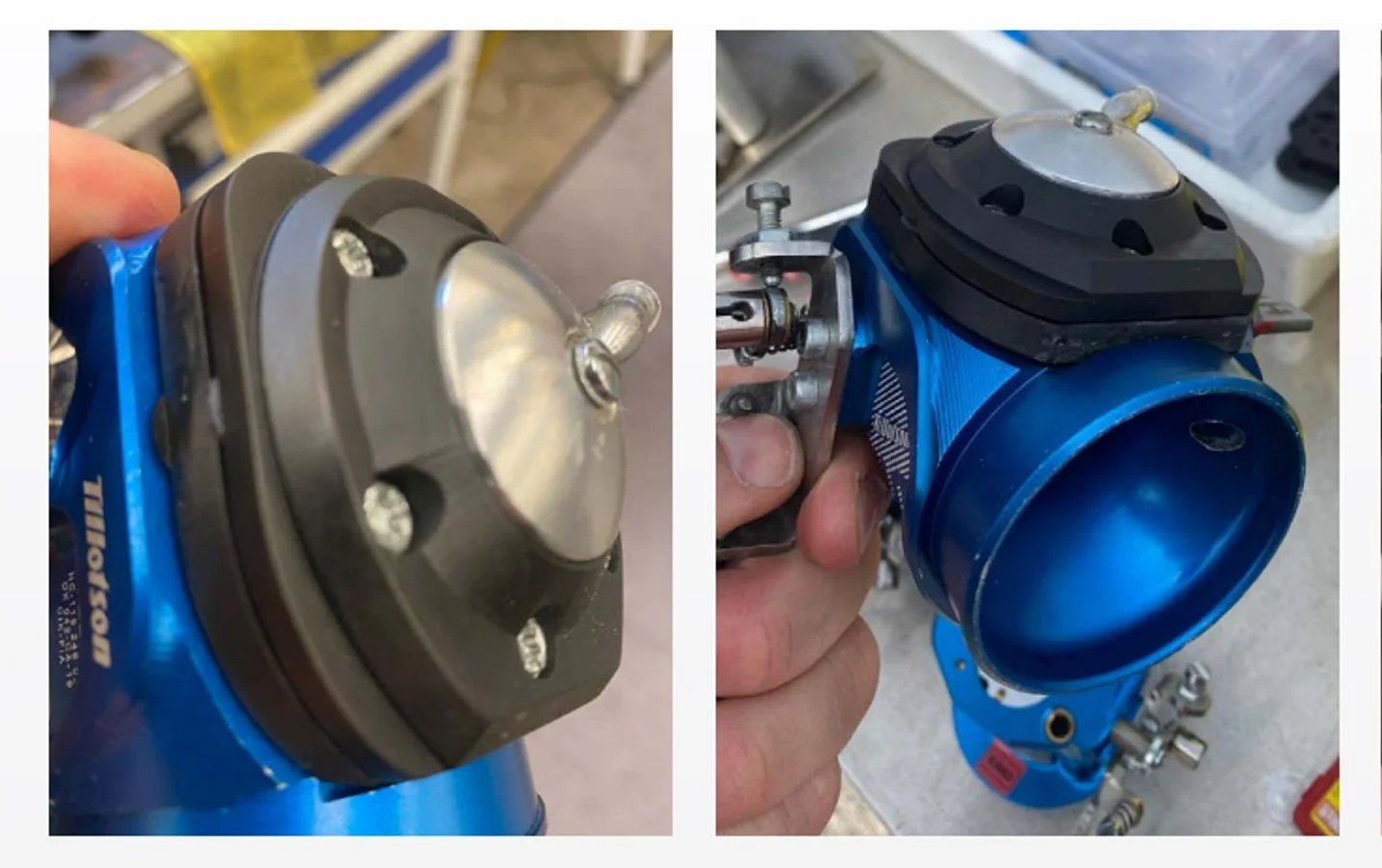

Assembly

After installing the newly 3D printed fuel pump body the customer immediately had great results. A more consistent power delivery and improved power. Making them about 0.2s faster each lap!